Cost vs. Quality: How to Balance Budget and Expertise When Hiring a Tank Inspection Company?

When it comes to tank inspections—whether for water, oil, chemical, or any industrial application—the stakes are high. Tanks are vital to your operations, and their integrity isn’t something you can gamble on. But here’s the tricky part: balancing your budget with the quality of service offered by tank inspection companies. How do you ensure you’re not overspending, but also not compromising on expertise and safety?

This isn’t just a financial decision; it’s a strategic one. The right tank inspection company can save you from costly repairs, compliance penalties, or even environmental disasters. In this blog, we’ll dive into the cost-quality equation and help you strike the perfect balance.

The True Cost of Cutting Corners

Let’s get one thing straight—opting for the cheapest inspection service might seem like a win for your budget, but it often leads to expensive consequences. A subpar inspection can miss critical issues like:

- Corrosion: Hidden rust spots that could lead to leaks.

- Cracks: Structural weaknesses that could escalate into failures.

- Sediment Buildup: Reduced tank efficiency and contamination risks.

In fact, the American Petroleum Institute (API) reports that improper inspections are one of the leading causes of tank failures in the U.S. And when you factor in potential repairs, downtime, and environmental cleanup, the initial “savings” vanish into thin air.

What You’re Paying for in Quality Inspections

High-quality inspections aren’t just about ticking boxes—they’re about ensuring your tanks meet operational, safety, and regulatory standards. Here’s what sets a reputable tank inspection company apart:

- Advanced Technology:

- Companies offering ultrasonic testing, 3D mapping, or drone inspections might charge more upfront, but these methods provide precise and comprehensive results.

- For example, drones equipped with high-resolution cameras can identify structural damage in hard-to-reach areas, saving time and reducing risks.

- Certifications and Expertise:

- Look for companies certified by the API, Steel Tank Institute (STI), or similar organizations. These certifications ensure technicians are trained to industry standards.

- Did you know that hiring an API-certified inspector reduces the risk of compliance violations by 25%?

- Thorough Reporting:

- A detailed inspection report is worth its weight in gold. It should outline existing issues, recommended repairs, and preventive measures.

- Cheaper services often skimp on reporting, leaving you in the dark about your tank’s true condition.

- Customer Support:

- Quality companies don’t just inspect—they partner with you. They provide ongoing support, maintenance tips, and clear communication.

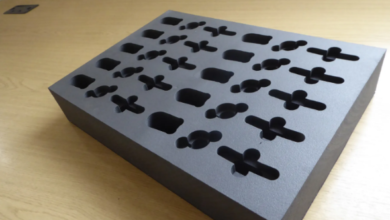

See also: Polystyrene Packaging: A Lightweight and Cost-Effective Solution

Tips for Balancing Cost and Quality

Now that we’ve established why quality matters, let’s talk about keeping things budget-friendly. Here are five practical tips to get the best of both worlds:

1. Assess Your Needs

Not all tanks require the same level of fiberglass tank inspection. A high-pressure chemical tank might demand more advanced methods than a water storage tank.

- Conduct a risk assessment to determine the inspection frequency and depth required for your specific tanks.

2. Request Multiple Quotes

- Don’t settle for the first company you find. Reach out to at least three reputable providers and compare their services.

- Be wary of companies that quote significantly lower prices than their competitors—it’s often a red flag.

3. Consider Long-Term Savings

- Investing in a higher-quality inspection can prevent costly repairs or replacements down the line.

- According to the NACE, preventive maintenance can save up to 40% on total lifecycle costs compared to reactive maintenance.

4. Check Reviews and References

- Online reviews and client testimonials can give you valuable insights into a company’s reliability and expertise.

- Ask for case studies or references from businesses similar to yours.

5. Negotiate a Package Deal

- If you have multiple tanks or require regular inspections, inquire about package deals or annual contracts. Many companies offer discounts for long-term partnerships.

Red Flags to Watch Out For

While it’s important to stay within budget, don’t fall for these common pitfalls:

- No Certifications:

- If a company can’t provide proof of certifications or industry affiliations, walk away.

- Rushed Inspections:

- A quality inspection takes time. If a company promises lightning-fast results without explaining their methods, be skeptical.

- Poor Communication:

- Transparency is key. If a company dodges your questions or doesn’t provide a clear breakdown of costs, they’re not worth your investment.

When Quality Wins, Everyone Wins

Balancing cost and quality isn’t about compromising—it’s about maximizing value. A top-notch inspection company ensures your tanks are safe, efficient, and compliant with regulations. This means fewer disruptions, reduced risks, and better peace of mind.

Remember, your tanks are more than just storage—they’re integral to your business’s success. Treating inspections as an investment rather than an expense can pay off in spades.

Final Thoughts

Choosing a tank inspection company doesn’t have to be overwhelming. By prioritizing certifications, technology, and reputation over price alone, you’ll ensure your tanks remain in top-notch condition without breaking the bank.

So, whether you’re managing a single water tank or an entire industrial network, take the time to find a partner who values quality as much as you do. Trust us—your bottom line will thank you.